Point Load Test#

Test Overview#

Point Load Tests (PLT) are quick, portable index tests used to characterize intact rock strength in the field or laboratory.

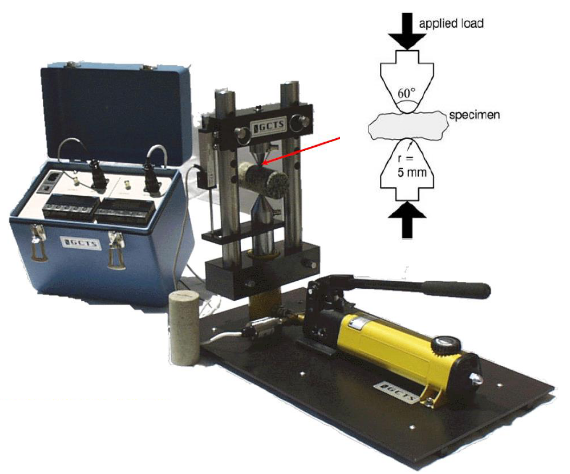

A specimen is loaded to failure between a pair of spherically-truncated conical platens (60° cone with ~5 mm radius tips):

Figure 1: PLT Tester Equipment#

The failure load \(P\) is recorded and the “Point Load Strength Index” is computed as

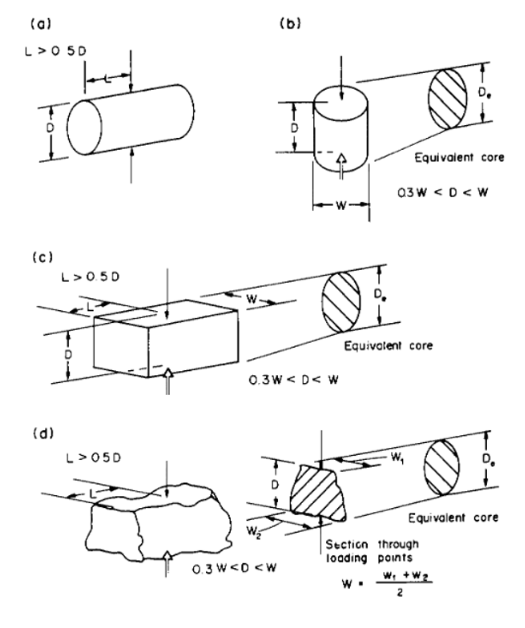

Where \(D_e\) is the “Equivalent Core Diameter” which represent the actual distance between load points. This distance is calculated differently according to the specimen shape:

Figure 2: Specimen shape requirements for (a) diametral test, (b) axial test, (c) block test, and (d) irregular test (ISRM 1985). [1]#

For the diametral test, \(D_e\) is equal to the core diameter. For the other cases, \(D_e\) is calculated as:

Where \(A = W \cdot D\) is the minimum cross-sectional area of a plane through the contact points.

Size Correction#

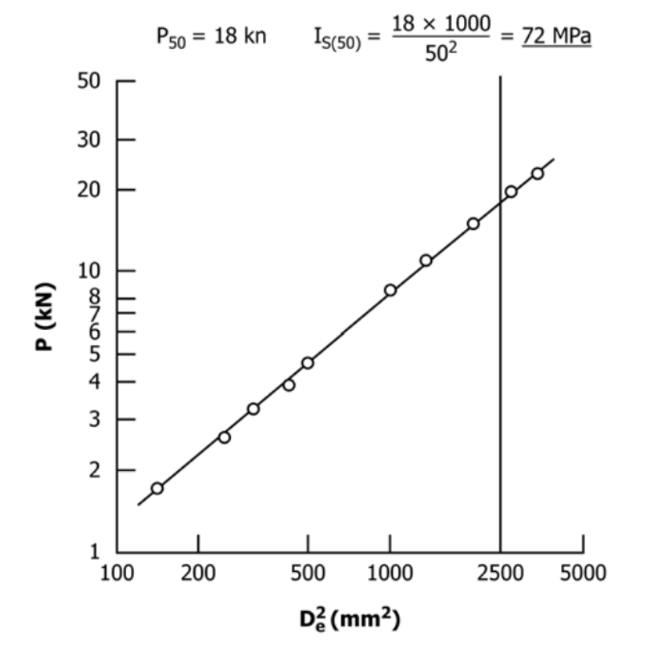

Since the value of \(I_s\) varies as a fucntion of \(D_e\), a size correction must be applied to get an unique PLT value for the rock sample and one that can be used for purposes of rock strength classification.

Therefore, the “Size-corrected Point Load Strength Index”, \(I_{s(50)}\) is used, which is defined as the value that \(I_s\) would have in a diametral test with \(D = 50\) mm.

The standard propose three ways of getting size-corrected results:

Conduct diametral tests on samples with \(D = 50\) mm or close to it (like NQ or NX).

(Most reliable) Perform the test over a range of \(D_e\) and plot the relation betweeen \(P\) and \(D_e\) in a log-log space:

Figure 3: Procedure for determination of \(I_{s(50)}\) from results at \(D_e\) other than 50 mm [2].#

Use a “Size Correction Factor”, \(F\), such that \(I_{s(50)} = F \cdot I_s\). This factor can be calcultaed by:

UCS Estimation#

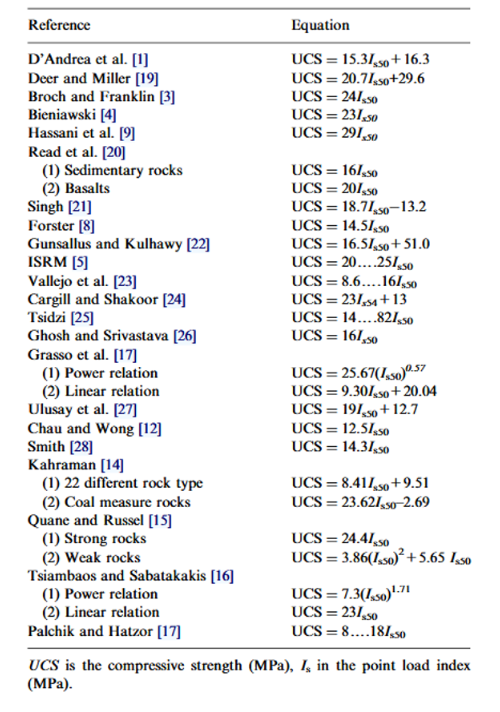

The Point Load Strength Index can be correlated with the Uniaxial Compressive Strength (UCS), providing a practical way to estimate UCS when direct testing is not possible.

Table 1: Equations correlationg the UCS to the point load index (Kahraman 2005) [3].#

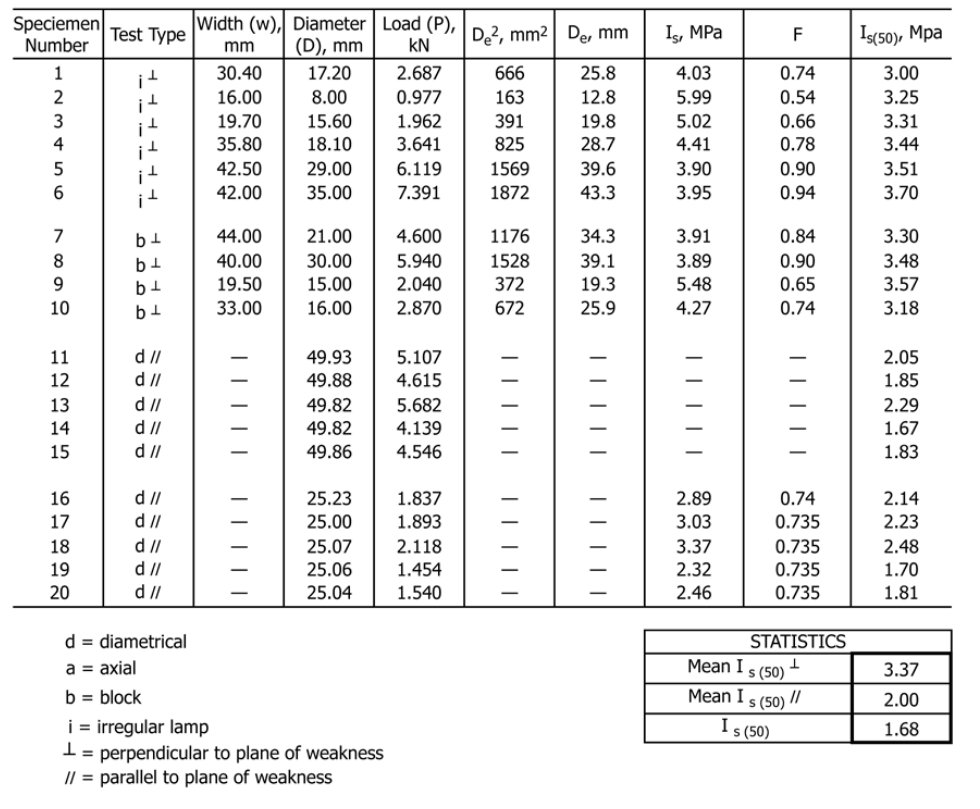

Common Data#

See how the input load is force (kN)? If any other kind of load (like pressure) is reported, it should be investigated what they are actually reporting, if it isn’t \(I_s\) or \(I_{s(50)}\), then the tests results are NOT valid.

Standards#

The “Point Load Test” (PLT) is regulated by the following standard:

GeoAssistant Implementation#

Creation#

To create a single PLT instance of each type by using:

from geoassistant import PLTTest

plt_diametral = PLTTest.createDiametralPLT(diameter=0.061, length=0.10, peak_load=10.)

plt_axial = PLTTest.createAxialPLT(diameter=0.061, length=0.10, peak_load=10.)

plt_block = PLTTest.createBlockPLT(width=0.06, height=0.05, length=0.10, peak_load=10.)

plt_irregular = PLTTest.createIrregularPLT(width1=0.06, width2=0.05, length=0.10, peak_load=10.)

To link PLT tests with drillholes, try using:

from geoassistant import PLTTest

## COMPLETE

plt_diametral = PLTTest.createDiametralPLT(diameter=0.061, length=0.10, peak_load=10.)