Q-System#

Barton et al. (1974) [1] developed the Tunnelling Quality Index”, Q, which is defined by:

\[Q = \dfrac{RQD}{J_{n}} \cdot \dfrac{J_{r}}{J_{a}} \cdot \dfrac{J_{w}}{SRF}\]

Parameters#

The following parameters …

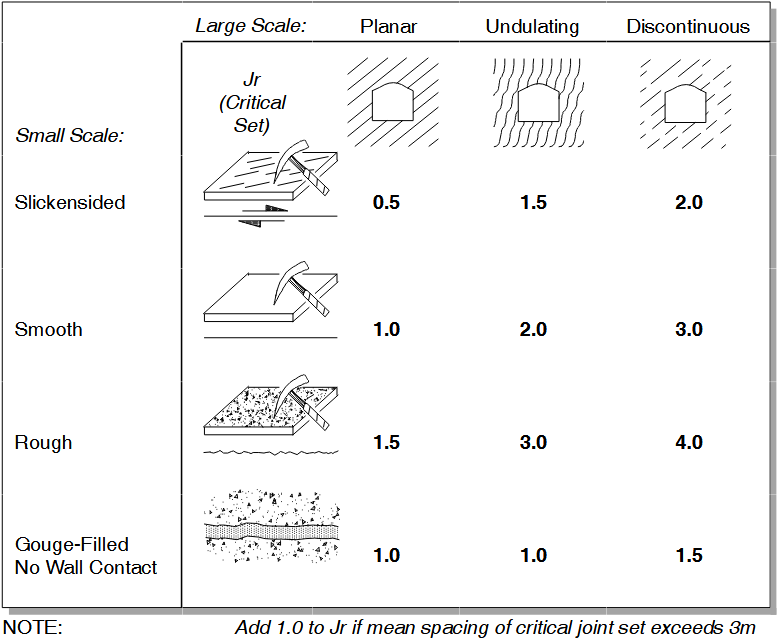

Jr: Joint Roughness Number#

Jr relates both large and small scale surface texture for discontinuities:

Figure 1: Joint roughness number (from Hutchinson & Diederichs 1996) [2]#

Ja: Joint Roughness Number#

Ja describes the surface alteration and frictional resistance of the critical joint set and ranges from 0.75 (favourable) to 20 (unfavourable).

Description (Critical Joint) |

Ja |

|---|---|

Tightly Healed |

0.75 |

Surface Staining Only |

1.0 |

Slightly Altered Joint Walls. Sparse Mineral Coating. |

2.0–3.0 |

Low Friction Coating (Chlorite, Mica, Talc, Clay) < 1 mm thick |

3.0–6.0 |

Thin Gouge, Low Friction or Swelling Clay (1–5 mm thick) |

6.0–10.0 |

Thick Gouge, Low Friction or Swelling Clay (> 5 mm thick) |

10.0–20.0 |