MRMR 1990#

The “Mining Rock Mass Rating”, MRMR, system was first presented by Laubscher in 1977 [1], althought the commonly used first version is the one presented by himself in 1990 [2].

The following makes reference to the MRMR 1990’s version.

Parameters#

The following parameter descriptions are based on the 1990 version [2].

Intact rock strength#

IRS [MPa] Range |

Rating |

|---|---|

> 185 |

20 |

165–185 |

18 |

145–164 |

16 |

125–144 |

14 |

105–124 |

12 |

85–104 |

10 |

65–84 |

8 |

45–64 |

6 |

35–44 |

5 |

25–34 |

4 |

12–24 |

3 |

5–11 |

2 |

1–4 |

1 |

RQD#

Fracture Frequency#

Average per metre |

1 set |

2 set |

3 set |

|---|---|---|---|

0,10 |

40 |

40 |

40 |

0,15 |

40 |

40 |

40 |

0,20 |

40 |

40 |

38 |

0,25 |

40 |

38 |

36 |

0,30 |

38 |

36 |

34 |

0,50 |

36 |

34 |

31 |

0,80 |

34 |

31 |

28 |

1,00 |

31 |

28 |

26 |

1,50 |

29 |

26 |

24 |

2,00 |

26 |

24 |

21 |

3,00 |

24 |

21 |

18 |

5,00 |

21 |

18 |

15 |

7,00 |

18 |

15 |

12 |

10,00 |

15 |

12 |

10 |

15,00 |

12 |

10 |

7 |

20,00 |

10 |

7 |

5 |

30,00 |

7 |

5 |

2 |

40,00 |

5 |

2 |

0 |

Joint Condition#

Large-scale Expression#

“Sub-section A caters for the large-scale expression of the feature, such as across a drift or in a pit face.”

Description |

Dry |

Moist |

Mod. pressure (25–125 lt/m) |

High pressure (>125 lt/m) |

|---|---|---|---|---|

Multi wavy directional |

100 |

100 |

95 |

90 |

Uni wavy directional |

95 |

90 |

85 |

80 |

Curved |

85 |

80 |

75 |

70 |

Slight undulation |

80 |

75 |

70 |

65 |

Straight |

75 |

70 |

65 |

60 |

Small-scale Expression#

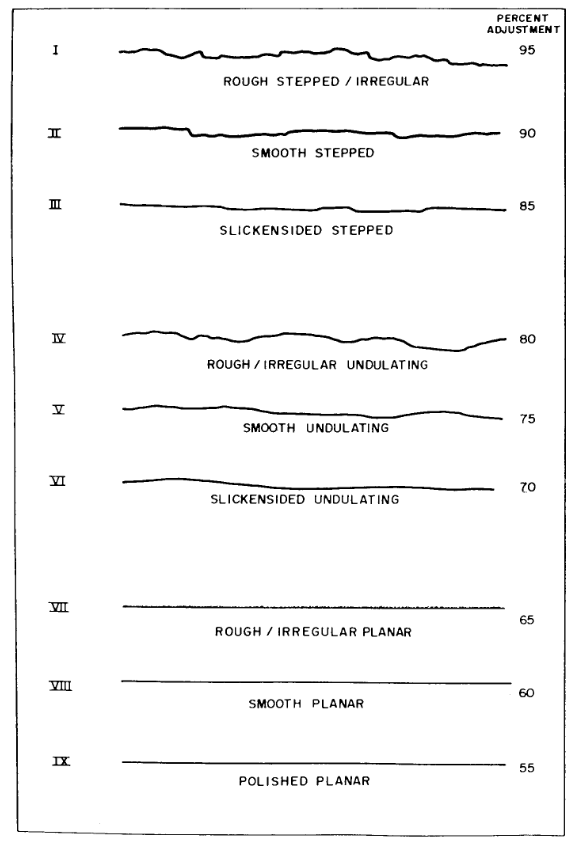

“B assesses the small-scale expression and is based on the profiles shown…”

Figure 2: Joint roughness profiles.#

Description |

Dry |

Moist |

Mod. pressure (25–125 lt/m) |

High pressure (>125 lt/m) |

|---|---|---|---|---|

Rough stepped/irregular |

95 |

90 |

85 |

80 |

Smooth stepped |

90 |

85 |

80 |

75 |

Slickensided stepped |

85 |

80 |

75 |

70 |

Rough undulating |

80 |

75 |

70 |

65 |

Smooth undulating |

75 |

70 |

65 |

60 |

Slickensided undulating |

70 |

65 |

60 |

55 |

Rough planar |

65 |

60 |

55 |

50 |

Smooth planar |

60 |

55 |

50 |

45 |

Polished |

55 |

50 |

45 |

40 |

Wall Strength Contrast#

“Section C is applied only when there is a distinct difference between the hardness of the host rock and that of the joint wall”

This means that Factor C is only activated or modified when there is a noticeable contrast in mechanical properties between:

The intact rock mass (host rock), and

The material or surface along the joints (joint walls), which might be altered, infilled, or weathered.

Description |

Dry |

Moist |

Mod. pressure (25–125 lt/m) |

High pressure (>125 lt/m) |

|---|---|---|---|---|

Joint wall alteration weaker than wall rock and only if it is weaker than the filling |

75 |

70 |

65 |

60 |

Infill#

Description |

Dry |

Moist |

Mod. pressure (25–125 lt/m) |

High pressure (>125 lt/m) |

|---|---|---|---|---|

Non-softening and sheared material – Coarse |

90 |

85 |

80 |

75 |

Non-softening and sheared material – Medium |

85 |

80 |

75 |

70 |

Non-softening and sheared material – Fine |

80 |

75 |

70 |

65 |

Soft sheared material (e.g., talc) – Coarse |

70 |

65 |

60 |

55 |

Soft sheared material (e.g., talc) – Medium |

60 |

55 |

50 |

45 |

Soft sheared material (e.g., talc) – Fine |

50 |

45 |

40 |

35 |

Gouge thickness < amplitude of irregularities |

45 |

40 |

35 |

30 |

Gouge thickness > amplitude of irregularities |

30 |

20 |

15 |

10 |